WANGEN X-UNIT

Protect your AD plant and boost biogas yield with the WANGEN X-UNIT from Agrico

Anaerobic digestion pump specialist Agrico has unveiled the new and improved WANGEN X-UNIT; a revolutionary one-step biogas optimisation solution that protects AD plants from damage by harmful contaminants AND increases feedstock surface area to supercharge the digestion process.

The X-UNIT’s innovative debris catcher prevents foreign objects from entering the AD system, safeguarding pumps, mixers, pipework and tanks. In addition, its high-performance chopping blades reduce AD feedstock to a fine, porridge-like consistency to optimise the anaerobic digestion process. The result is an easy-to-operate, energy-efficient system that extends the lifespan of valuable equipment, increases operational uptime and maximises biogas yield, boosting an operator’s bottom line.

A UK first

Already established in Europe, a new and improved version of the X-UNIT is now available to UK AD plant operators for the first time thanks to Agrico’s partnership with WANGEN. The preferred pump supplier to 40% of the British biogas industry, Agrico has been the sole UK stockist for WANGEN’s range of biogas pumps and mixers for over 10 years and General Manager John Tame is delighted to introduce this latest innovation to the market: “Having seen first-hand the considerable damage caused to downstream equipment by contaminants like bone, metal, stones and grit entering an AD plant, I am excited to showcase the new and improved X-UNIT to the UK industry, where it can play an important role in protecting biogas systems. What’s more, its ability to help plant operators extract the maximum gas yield from every tonne of feedstock will be a welcome bonus, particularly in the current climate where competition for feedstock is fierce and gas prices are at a record high.”

Prolonging equipment lifespan

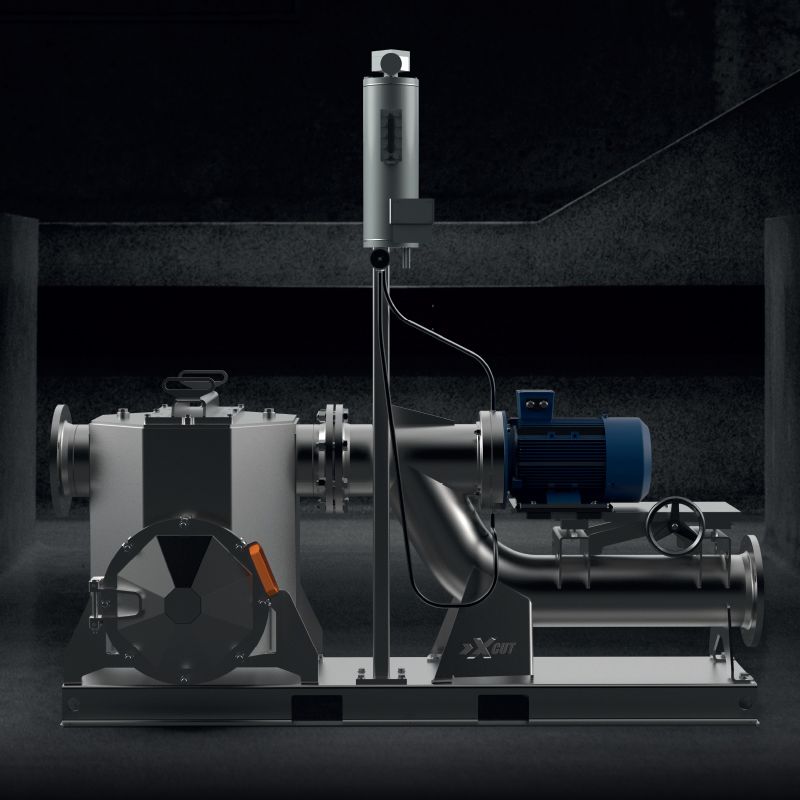

Failing equipment, reduced digester headspace, and poor biogas conversion rates are challenges that affect many AD plant operators’ profit margins, and the X-UNIT aims to address each of these hurdles in turn. A modular system that can be retrofitted to the suction side of all makes of positive displacement pumps, such as progressive cavity and lobe, it comprises two elements: the X-CUT, a high-performance chopper; and the X-TRACT, which separates contaminants from feedstock.

As feedstock passes through the X-TRACT on its way to the digester tank, a reduction in velocity causes foreign objects such as stones, plastic, grit, bone or metal to fall into the base of the unit, where they are caught in a settling tank, or debris catcher. This features a large opening for easy removal of settled contaminants, preventing them from entering the wider AD system and subsequently damaging valuable downstream equipment such as pumps, mixers and pipework.

Not only does this extend equipment lifespan, preventing plant operators from having to prematurely replace expensive kit, it also reduces downtime caused by equipment failure due to blockages and wear. “As AD is a constant process, every minute that a plant is not operational has a direct effect on its ability to produce gas; increased uptime therefore equals more profit,” explains John.

Maximising tank headspace

In addition, without the X-UNIT to screen out debris, foreign contaminants would ultimately settle in one place – the floor of the primary digester tank. “A build-up of solids in the digester can have a severe impact on a plant’s success by reducing tank volume, also known as headspace,” states John. “The less volume inside the tank, the less biogas it can hold, resulting in reduced gas output and directly affecting a plant’s profitability. There is also the cost of removing the compacted sediment from the digester, which can reach hundreds of thousands of pounds. By preventing solids from entering the AD system in the first place, the X-UNIT protects plant operators from the risk of this expensive occurrence.”

Optimising biogas yield

After passing through the X-TRACT, the feedstock – now containing significantly reduced quantities of contaminants – moves into the X-CUT; a high-performance chopping unit operating at pressures of up to 6-bar and boasting speeds of up to 3,000 rpm. Its four double-edged blades finely chop the feedstock into a smooth, porridge-like consistency, reducing the risk of fibres wrapping around equipment or forming swim layers which can hinder digestion. Reducing feedstock particle size also results in a lower viscosity within the tank, improving mixing and helping the digestion process. But perhaps most crucially, the X-UNIT’s chopping ability increases a feedstock’s surface area. This provides easier access for the microbes in the digester, boosting the anaerobic digestion process and ensuring that the maximum amount of biogas can be extracted from each tonne of feedstock.

Ease of maintenance

The X-UNIT’s unique four-blade design also extends maintenance intervals. By simply unlocking two bolts, the low-cost cutting blades can be switched around to double their lifespan. This ease of access also facilitates rapid maintenance, as John explains: “With the removal of just a few bolts and a simple turning of a handle, the motor can be slid out, a blanking plate can be inserted, and blade changeover can be actioned, while the rest of the unit continues to run as normal. The X-UNIT’s simple design makes it cost-effective and super easy to maintain.”

Featuring a maximum flow volume of 1,250 m3/h, low energy consumption, low wear costs and accessible parts for ease of maintenance, the X-UNIT is designed for longevity. “UK AD plant operators can now protect their investment and optimise their biogas output with the best of German engineering, backed up by on-the-ground, local sales and servicing support from Agrico,” adds John.

For more information on the WANGEN X-UNIT or any of Agrico’s range of leading pumping, mixing and agitating equipment, contact 01785 851240 or email office@agricopumps.co.uk